DevelopmentINTRODUCTION

2019

New production base put into operation

2019

Robot application

The self-developed line frame robot and the outsourced 6-axis multi-joint robot were successfully put into pulp molding production and industrialized.

2018

National recognition

National high-tech enterprise recognition

2016

Industrialization

Tableware production line has been industrialized and successfully applied inShabot Zhongshan factory (America)and Qiaowang factory(China)

2014

Technological progress

The technology project of energy saving and consumption reduction in pulp molding production won the first prize of Science and Technology Progress of Guangdong Province.

2009

Break through

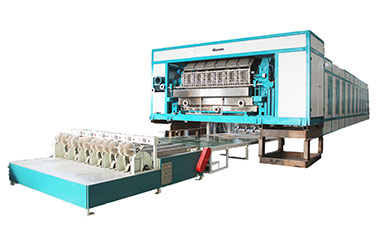

Our self-developed multiple molding machine with hanging dryer breaks through the traditional small-scale production mode, with high capacity and low energy consumption per product.

2004

Double Certification

We passed the "double certification" of quality system certification and product certification of China Packaging Certification Committee.We are the earliest enterprise among China counterparts to pass the "double certification".

2000

Fully auto integrated wet press production line

Guanghzou Nanya Pulp Molding Equipment Company was established with a registered capital of 5 million RMB. In the same year, we independently developed the fully automatic one-piece wet press production line.

1998

First Creation

Self-developed the first fully auto rotary drum egg tray/fruit tray production line. The equipment has high capacity, high production efficiency and industrialization.

1996

First Creation

Joint venture with Hong Kong capitalist to establish Guangzhou Nanya Baoda Equipment Co. Developed and produced the first pulp molding industrial packaging production line in China, achieving a zero breakthrough in the independent R&D

1994