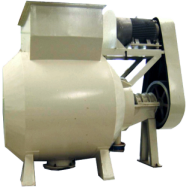

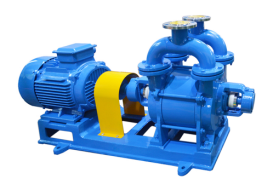

The semi-automatic reciprocating machine production line consists of pulp making system, forming system, drying system, vacuum system, high pressure water system and air pressure system, which can produce a variety of paper products. The production line takes waste paper such as waste newspaper, waste carton paper, trimmings and other waste paper as raw material, which is blended into a certain concentration of pulp by hydrolysis and filtration, water injection and other processes, and formed into wet products by vacuum adsorption on customized molds through the forming system, and finally dried and hot pressed in the dryer and then stacked to completion.

①Product forming and drying is done by semi-automatic equipment, the process requires manual transit.

②Drying methods are various, you can choose dryer, drying room or natural drying.

③Applicable to the production of egg trays, egg cartons, fruit trays, coffee trays, hospital trays, industrial product liner packaging, etc.

Pulp molding egg tray/egg carton/fruit tray production line series- Semi-automatic reciprocating machine production line | |||||

ES1200-A Production Line Data | |||||

Mold plate size |

1200*800mm |

Capacity |

1200-1500 pcs/h | ||

Forming type |

Vacuum pulping |

Drying method | Dryer / drying room / natural drying |

Control method |

Manually |

Material consumption |

80~100kg/h |

Power consumption |

40~45kw/h

|

Water consumption |

300-400kg/h |

Dryer size |

20*2.5*3m |

Transfering method | By worker | ||

Worker |

5-6 workers/shift

|

Workshop size | ≥200㎡ |

Installed power |

60kw |

Other Information | |||||

Place of origin |

China |

Brand |

NANYA |

Certification |

CE,TUV,SGS, ISO9001(optional) |

Payment method |

Cash,L/C, T/T, Western Union |

Packing method |

By export standard |

Delivery time |

60-120 days |

Remark: The above data is for reference only and is subject to change as technology is updated. | |||||

1. Are you a manufacturer or a trader?

A: Guangzhou Nanya Pulp Molding Equipment Co., Ltd. is a manufacturer with near 30 years of experience in developing and producing pulp molding equipment. We have become very proficient in the production process of equipment and molds, and we can provide our customers with mature market analysis and production advice.

2. What kind of molds can you produce?

A: At present, we have four main production lines, including pulp molded tableware production line, egg tray/egg carton/fruit tray/coffee cup tray production line, general industrial packaging production line, and fine industrial packaging production line. In addition, we can also do disposable medical paper tray production line. At the same time, we have professional design team, we can customize the mold for customers according to their requirements, and the mold will be produced after the samples are inspected and qualified by customers.

3. What is the payment method?

A: After signing the contract, payment will be made in accordance with 30% deposit by wire transfer and 70% by wire transfer or spot L/C before shipment. The specific way can be agreed.

4. What is your after-sales service?

A: ①Provide 12 months warranty period, free replacement of damaged parts during the warranty period.

②Provide operation manuals, drawings and process flow diagrams for all equipment.

③After the equipment is installed, we have professional personnel to guide the buyer's staff on the operation and maintenance methods.

④We can guide the buyer's engineer on production process and formula.